PIELDS ENGINEERING

Flare Solutions

The flaring of gas from the flare stack during normal operations is referred to as Normal Flaring.

In addition to wasting valuable resources, this practice also contributes to environmental degradation due to CO2 emissions.

To address this issue, Pields Engineering's Vent Analysis employs technologies such as detection of gas leakage, process analysis,

and measurement of flare gas flow. These technologies help collect essential operational data, including operation status, gas status,

and leakage information, and facilitate the economical design of FGRUs.

-

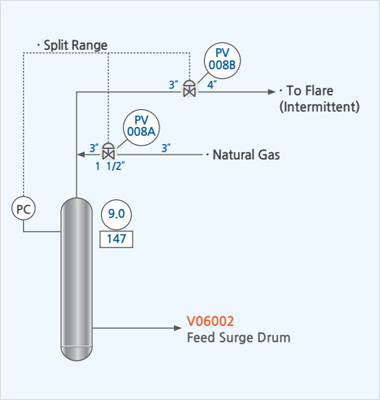

Step1 Process Analysis

Analyze the causes for the generation of

waste gas during factory operations and

the operating conditions to reduce emissions

through changes in process or operations. -

Step2 Leak Detection

Reduce waste gas emissions

by detecting leaks and repairing or

replacing valves that shut off waste gas

emissions connected to flare systems. -

Step3 Flow Measurements

Measure flow to determine the source and

cause of gas emissions in plant operations.

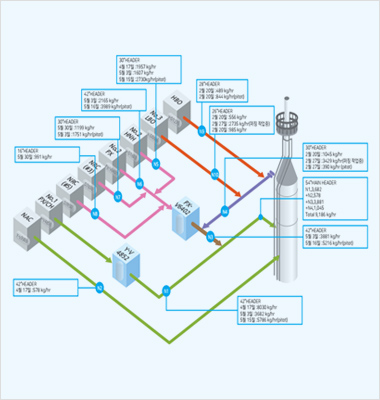

This example demonstrates how Pields Engineering reduced

Cost by performing a Vent Analysis.

SK Incheon Petrochemical

75% reduction in the generation of flare gas (4,000 Nm3/h 1,000 Nm3/h)

- Annually 7 Million dollar of Flaring Gas reduced.

- Annually 2 Million dollar of Steam Injection reduced.

- No more of residence people’s compliant

- Flare operation optimized, safety improved

- Total project period : 9 month

Iran’s Tabriz Oil Refining Company

80% reduction in the generation of flare gas (10,000 kg/h 2,000 kg/h)