PIELDS ENGINEERING

Flare Solutions

Pields Engineering has extensive experience in designing

Flare systems and can reduce Flare capacity through Dynamic Analysis, SIS (HIPS).

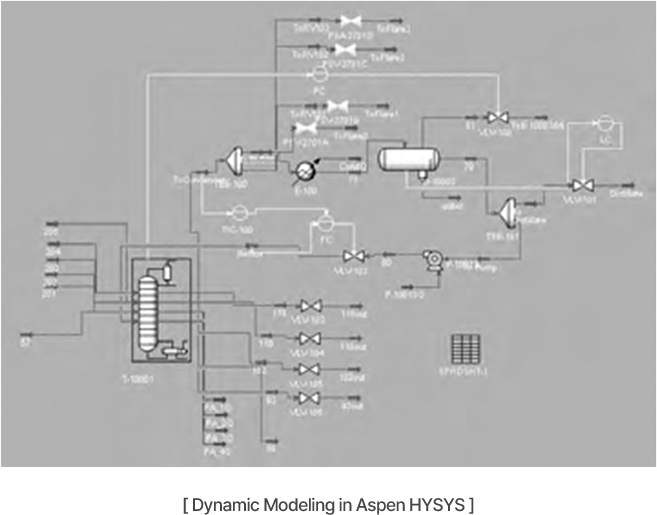

Dynamic Simulation

The criteria used to calculate the flare load—such as feed heat from the reboiler, the rate of rise in internal pressure, and the amount of vaporizable liquid in

the residue—can change over time.

Dynamic simulation accounts for these changes, providing a realistic picture of the discharge from each tower to the flare.

Dynamic Simulation is typically used to review flare capacity during the revamping phase rather than in the early stages of plant construction.

This is a better approach because dynamic simulation requires detailed information, such as unit sizing, which is usually not available early on.

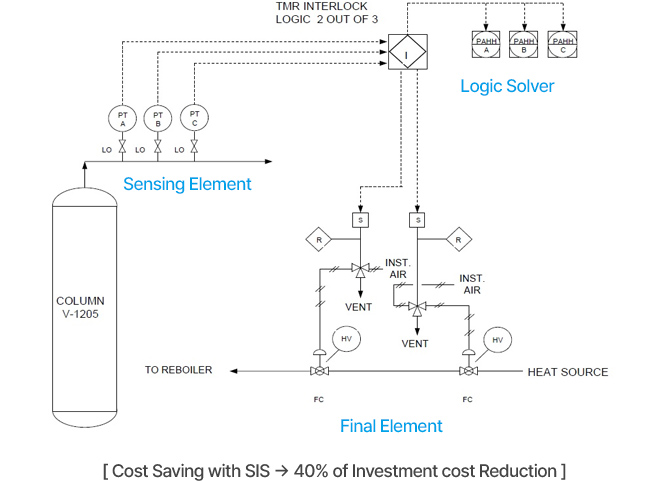

SIS (HIPPS System)

Also known as a High Integrity Protection System (HIPS), this widely used approach shuts off heat sources such as steam in the event of a plant fault before the pressure buildup causes a safety valve to open.

- SIS

-

- Reduce Header Line Size

- Reduce Flare Stack Size